A system for tool monitoring

-

The most effective way to monitor tools!

-

UT-Tm®- Basic System Tool and vibration monitoring system

The UT-Tm® system is control- and machine-neutral and can be integrated into machines that are up to 20 years old. Open for all commercially available operating platforms, the system detects wear-related tool breakage, missing tools and tool wear and is therefore predominantly also used to prevent them. In addition, UT-Tm®-Basic offers transparency in the processes, e.g. via measured active power or vibrations at the spindle. At the same time, this measured data can be used to optimise the cutting values. This means that higher feed rates can be tested or tools can be run until they wear out. All in all, the UT-Tm® system is an efficient investment for reducing the cycle times on a machine tool.

-

UT-Tm® in detail

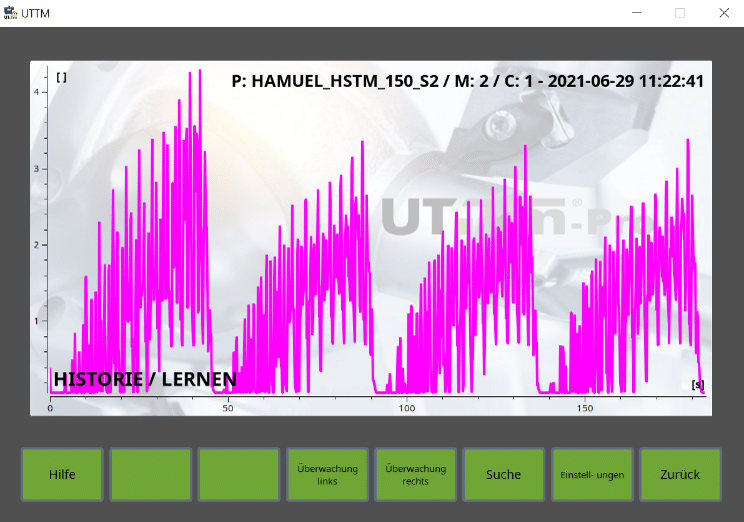

Visualisation in the learning process: Tools and machining operations are automatically learned within defined limits depending on the power, signal curve and machining time. The calculations of the limits can be carried out dynamically or statically. Of course, these limits or settings can be individually defined and manually optimised.

-

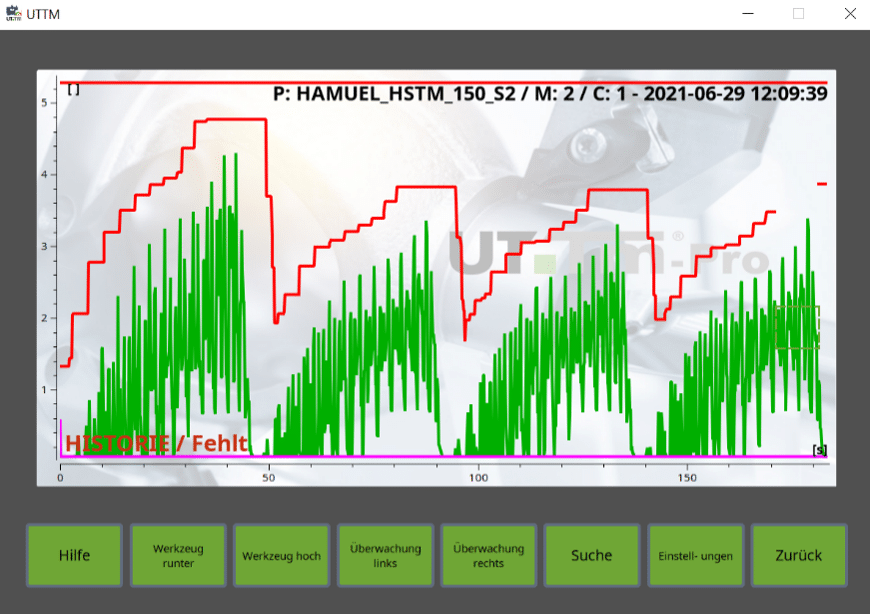

Visualisation in monitoring mode (tool breakage/tool missing)

Tools are monitored for breakage or tool missing with different strategies depending on the type of machining. The strategies in the overview:

- Real-time status and process security

- Detection of double machining on the workpiece

- Current and detailed recording of processes

- Protection against destruction of follow-on tools

- Detection of programme changes (e.g. cutting parameters)

- Monitoring during tool change (length correction)

So by protecting this active process monitoring, man and machine are protected.

-

The visualisation of the tool table and the monitoring number

The current NC programme shows all monitored tools in the individual machining processes. From the analysis of each machining step, individual process and tool optimisations can be derived in this area.

-

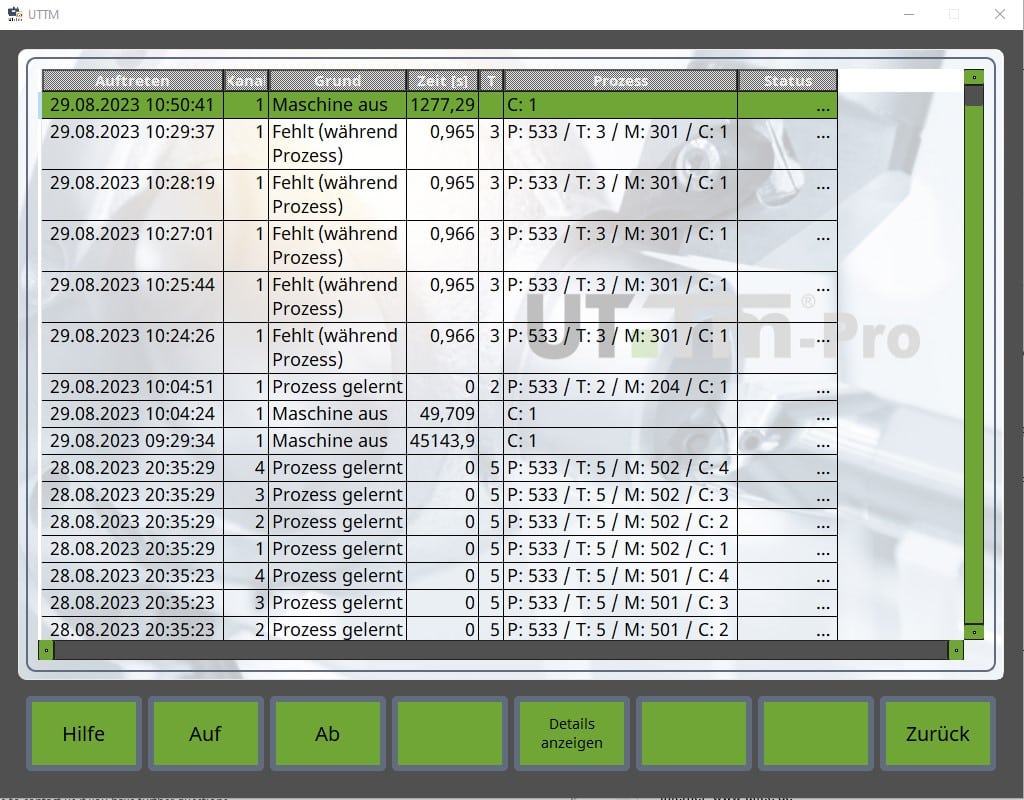

Visualisation of the alarm table and analysis of times

- As already mentioned, the NC programme shows all monitored tools with the individual machining operations. In addition, cutting and cycle times can also be analysed.

-

Visualisation in monitoring mode (wear monitoring)

Visualisation of the wear of the tool

During milling, drilling and other machining operations with defined cutting edges, wear occurs that can have a negative effect on the quality of the workpiece (dimensional accuracy, surface quality …). There are typical signs for each type of wear. This makes it possible to identify a trend by means of different force absorptions.

However, these typical signs can also lead to hair and comb cracks. In addition, stretching and shrinkage often occur in the material due to temperature fluctuations.

In the event of a plate breakout, the system intervenes immediately to prevent greater forces that could lead to destruction, tool holder, machine, workpiece…).

All in all, precisely definable tool service lives increase economic efficiency.

-

Optional but useful

UT Tm® Analyzer Viewer

- Through this optional extension, the system not only detects wear-related tool breakage, missing tools and tool wear, but also helps to detect and prevent them. It also protects the machine tool and workpieces from damage. In addition, incorrect parameterisation of the process data of feed and speed can lead to unnecessarily high non-productive times and main times. With the UT Tm® Analyzer Viewer, this source of error can be eliminated and high damage prevented.

-

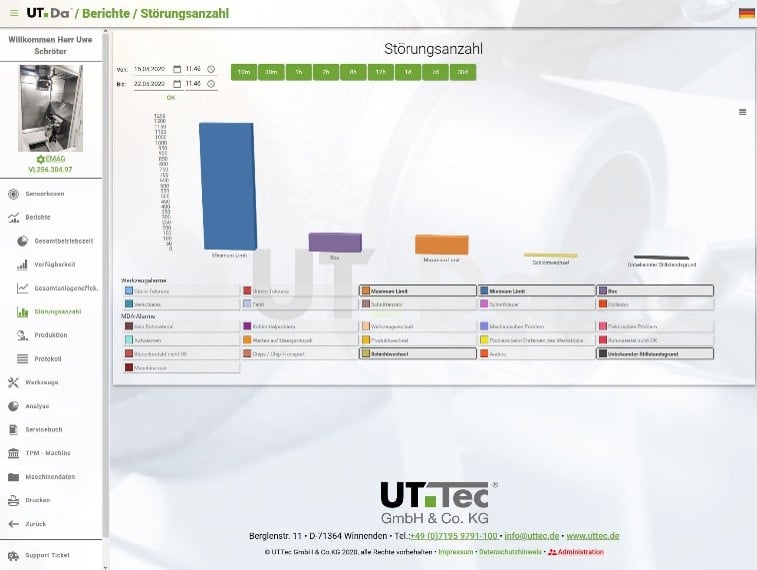

Server Solution UT Da®

- Visualisation of several machines with all process data in connection with the UT-Tm® process monitoring system.

- Visualisations and analyses of tools and production within 30 days.

- Visualisation of the MDE interface - 14 different MDE messages are stored and can be called up by the operator at the touch of a button

- Applicable at several locations

- Multilingual solution

-

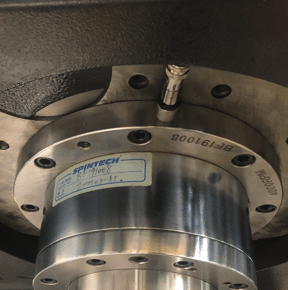

Collision monitoring UTCm®

Hardware extension for collision monitoring and multi-variable evaluation: 3D vibration sensors from UTTec enable active power analysis to be extended to include the mechanical component “vibration”. For this multi-variable evaluation, both variables are combined into one signal. The vibration sensors extend the system by the possibility to monitor the machine for collision.

-

Connection to the customer network

By expanding with UT-Tm®-Pro, information can be sent via a separate network interface with integrated firewall from the machine tool to the customer’s own or company network. With this information, problems can be detected at an early stage. The system thus directly contributes to an increase in availability and productivity. By connecting the IoT gateway, dashboards or higher-level systems can be supplied with data.

-

Mobile analysis

- Export of process data (I4.0) - The UT-Tm® process monitoring system enables mobile devices to view process data such as alarms, MDE messages and cycle times.

- The operation and analysis of process monitoring in the network.

- Remote access to the UTTec systems

-

Industry 4.0

- Export of process data (I4.0) - The UT-Tm® process monitoring system enables the automated export of process data such as alarms, MDE messages and cycle times. The data can be made available for Big Data systems (i4.0) via the MQTT or JSON formats.