-

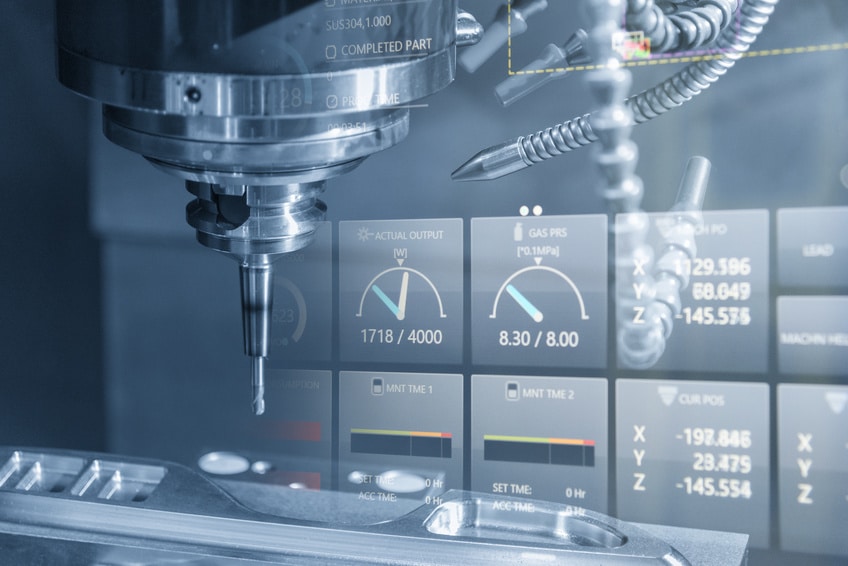

Modular from the First Workpiece to Series Production

Be it the machining of the fi rst workpiece, conceptualization and development of certain cycles, retooling or trainings, every module accompanying our processing is customized individually and in a practice-oriented manner based on the respective requirements and conditions. At any rate, you can always fi nd a suitable solution for any problem amongst good business partners.

-

Our standard modules in the overview

Machining studies & Machining cycles

We conduct detailed studies of machining processes, so that we can offer efficient solutions that are based on the respective.

- the production processes

- the process engineering

- the purpose of machining process

- the simulation of machining process

- the installation requirements

- and a recommendation for/decision on the automation

This module contains the conceptualization and development of certain cycles for specific machining tasks and consists of the following components:

- Development of new cycles

- Tool-life via parameters in the NC program

- Cycles for counters

Test machinings/retooling

During the fi rst weeks and/or the machining of the fi rst workpieces we accompany the production and phase in our know-how for:

- Support in manufacturing

- Individual trainings

- Knowledge based NC engineering

- Process monitorings

- Tool analyses

- Process auditing

- Tool optimization

Production supervision

We bring in our support during test machinings/retooling, during preliminary and final acceptance tests of the machine, when machines are relocated and during their recommissioning. That includes among other things:

- First workpiece machinings

- Retooling after relocating machines

- Machine capability

Trainings

It was Benjamin Franklin who told us, “an investment in knowledge pays the best interest”. Interest, which pays off quickly with our training program in matters of competitiveness. Using our comprehensive offer for courses on operating, programming and maintenance, our customers can see to it that they have a competitive edge on the necessary knowledge and are able to react to new requirements fl exibly and in good time. Individually, means to us:

- for every level of knowledge

- a wide-ranging offer in training made for beginners and on to experts

- learning with a practical orientation

- an ideal mix of theory and practice makes sure that knowledge is conveyed sustainably