UT-Cm®-PRO

This system is not only used to detect a collision, spindle analysis and logbook of the spindle, but also helps to identify it and prevent major damage

A system for collision and spindle monitoring with analysis

-

The most effective way to monitor collisions and vibrations!

- Collision alarm less in 2ms.

- Historical trend statistics

- FFT analysis

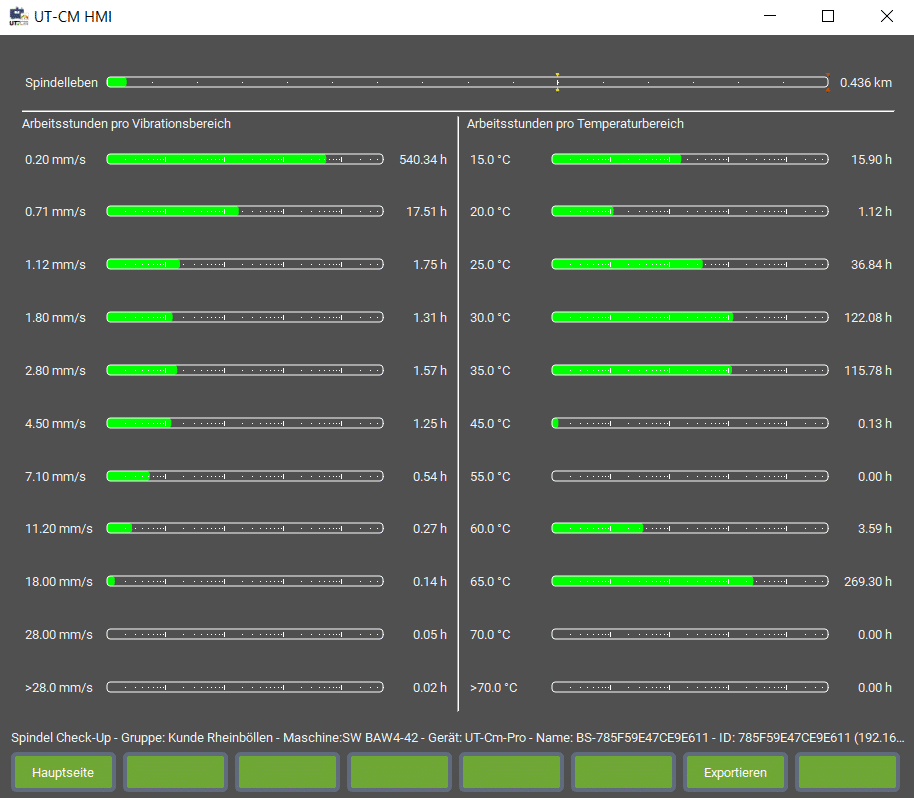

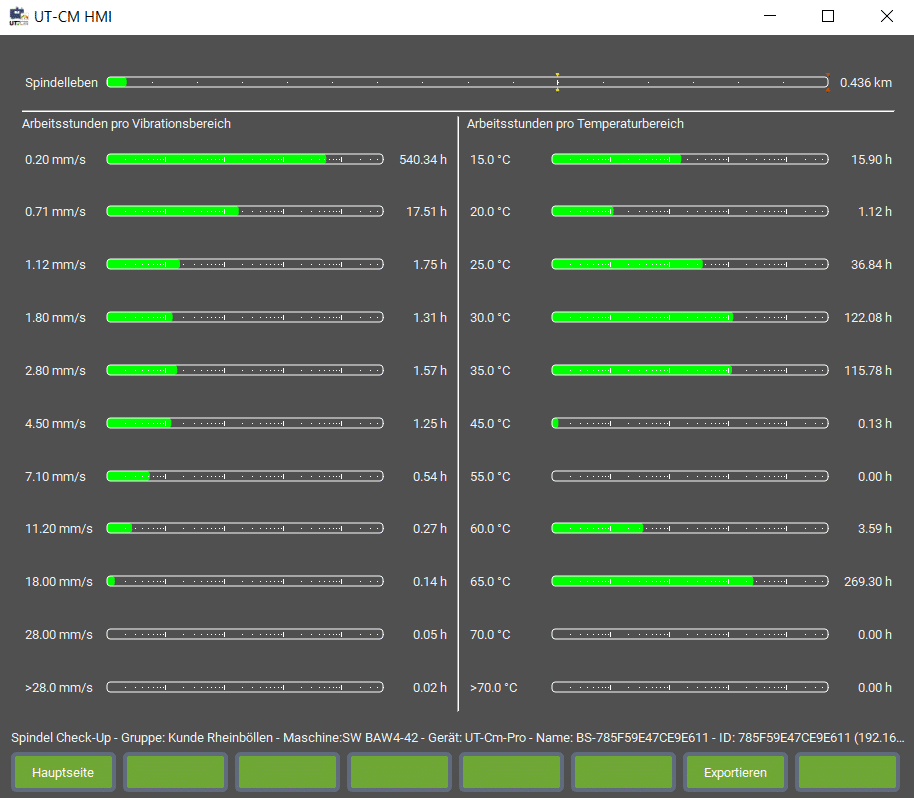

- Spindel Check UP

- Temperature alarm

- Transport monitoring

- Sensor with M12x1 and 42mm long

-

UT-Cm®-PRO version – Overview of all functions

UTTec UT-Cm®-PRO for Machine Tools is a system for the monitoring and control of machine tools, which the following purposes:

- Collision alarm less in 2ms.

- Sensor with M12x1 and 42mm long

- Overloading alarm

- Temperature alarm

- Programmable limits

- Events data logging

- Transport monitoring

- Real-time data for process-monitoring

- HMI (Windows XP, Win7, WIN10 , WIN11)

- UT - Cm® - Network – Software

- FFT analysis, wide bandwidth 10kHZ

- Historical trend statistics

- Continuous monitoring (5 days battery)

- Service history book

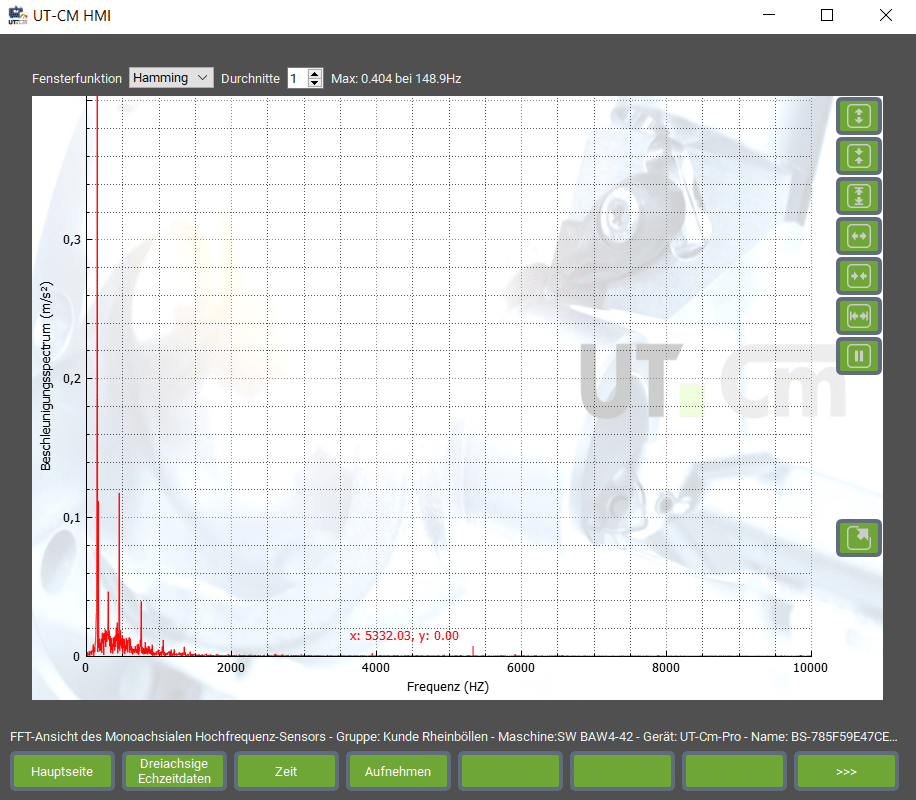

- FFT-Analyse mit einer Bandbreite von 10 kHz

- Spindle fingerprint (analysis of liftime)

- Spindle Check UP (the innovative tool for maintenance planning and asset management)

-

Always connected

The always-connected interface and multi-platform software allow to have the full control anywhere, obtaining the maximum results from your machine.

-

Dashboard

HMI UT-Cm® was developed to guarantee simplicity and intuitiveness in order to make you understand all the useful information at a glance. The system allows the interaction with more sensors to facilitate the complete monitoring of your machines.

The system enables interaction with several sensors as a complete monitoring of your machines facilitate.

-

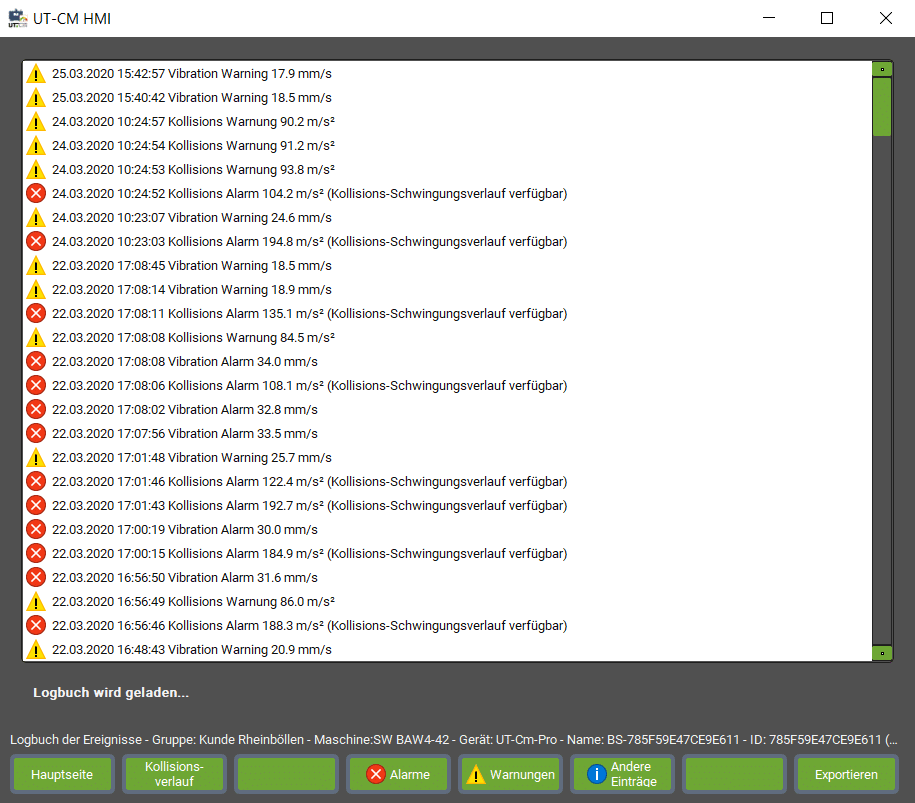

Events – Logbuch Details

The advantage of the events session is to look at your machine history, recording all activities with an intuitive infographic that includes the following functions:

Alarms, Warnings, Check-Up and Downtimes.

-

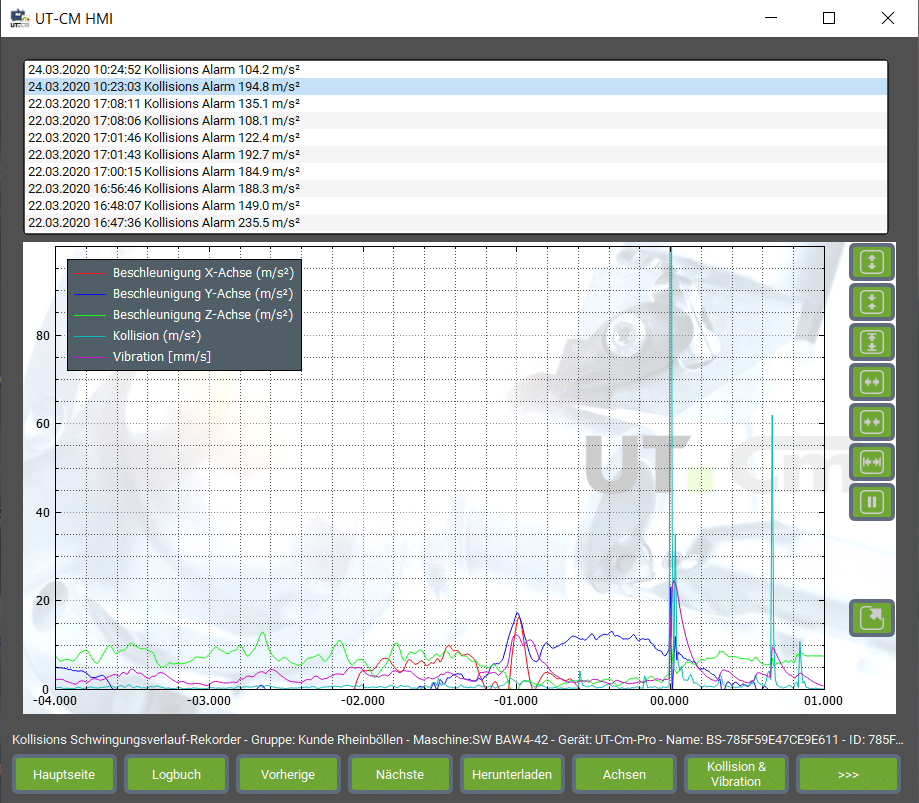

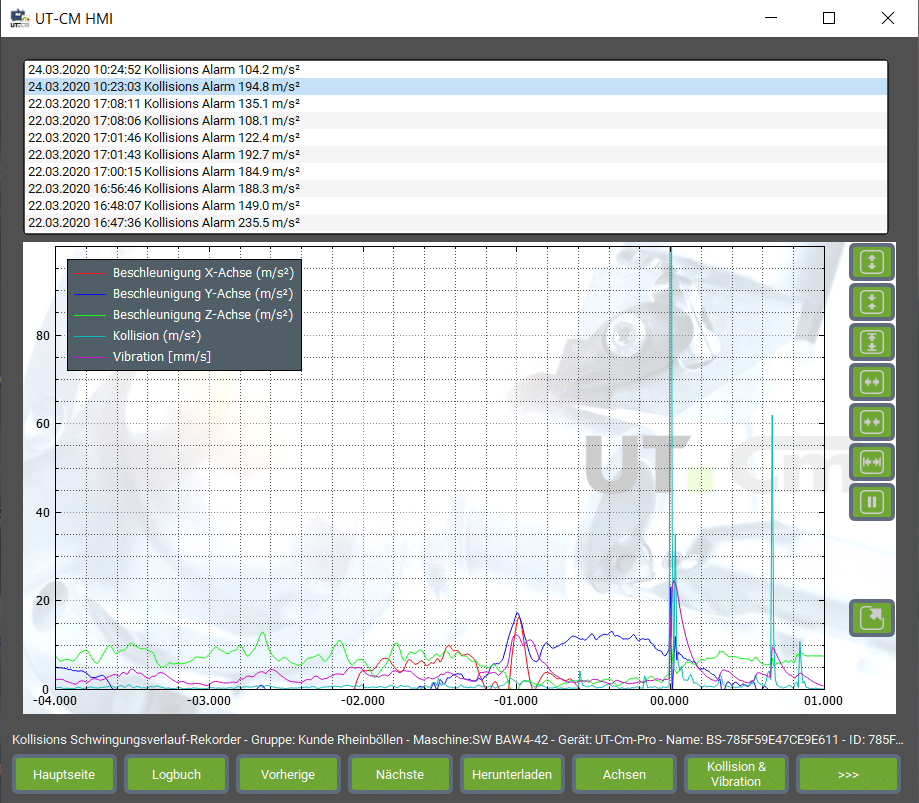

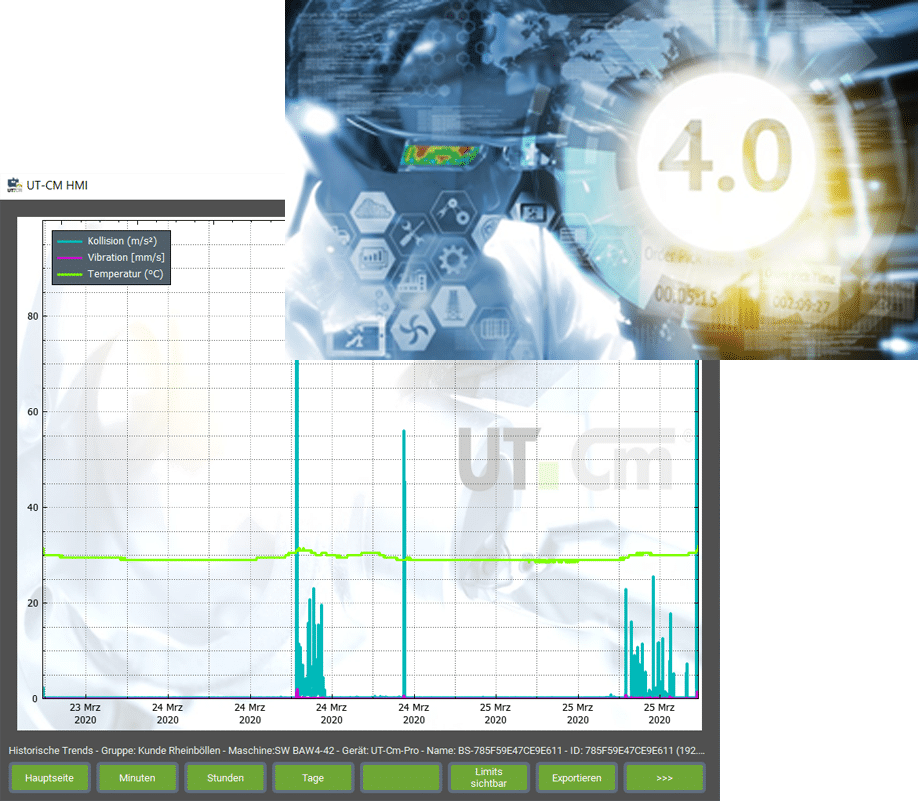

Collisions course

In the case of collision the system will allow you to examine in a greater detail the waveform during, before and after the event.

-

Real Time Data – Status RMS AXIS

Through the 3 factors visualization you can monitor in a single moment the productive process. The HMI UT-Cm® allows to export the evident information in every moment in real or non-real time, to manage data in complete autonomy.

-

Trend

Understanding trends, creating productivity statistics and sharing all the information are the bases of the mandatory evolving process today.

Thanks to the objective data colleted, HMI functions help you to plan production and maintenance at your best with the benefit of reduced the machine downtimes.

-

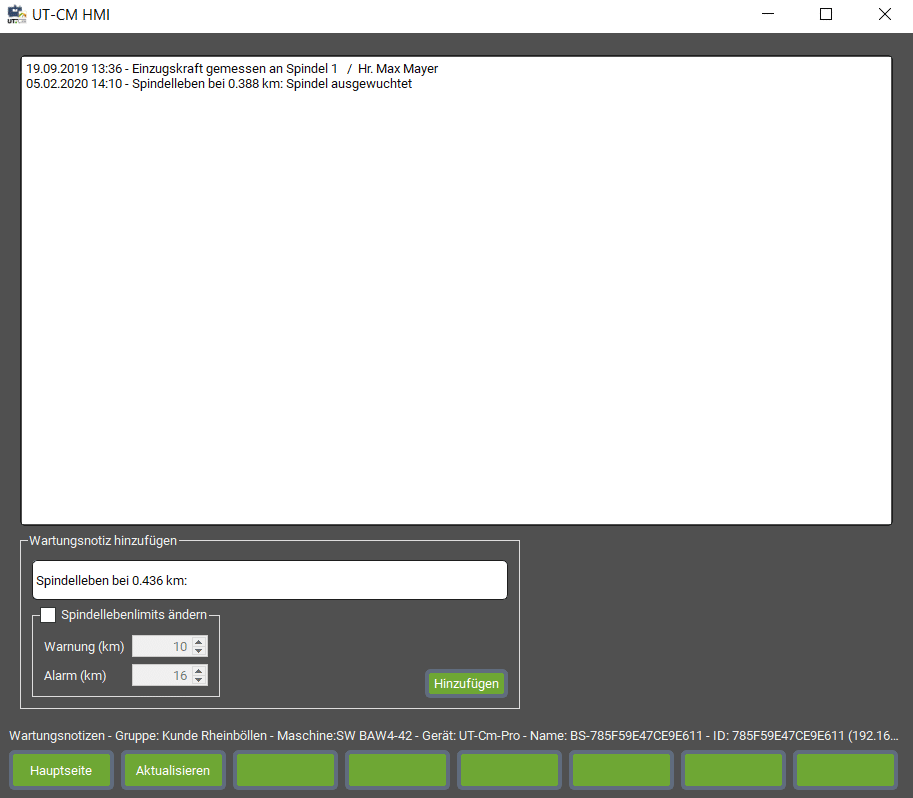

Maintenance Notes

Maintenance notes are understood to create exactly a service report of what everyone has performed on the spindle in maintenance or service. This information is the basis of the preventive maintenance history.

-

FACTORY CONTROL

With UT-CM Sensor you can enforce easily a line or remote assets innovative monitoring, thanks to the integration with SAM software (Smart Asset Monitoring).

Integration allows to have in a single dashboard the all connected assets state, some func-tioning KPI, registration of alarm events and real-time collision, vibration profiles and ma-chineries function.

-

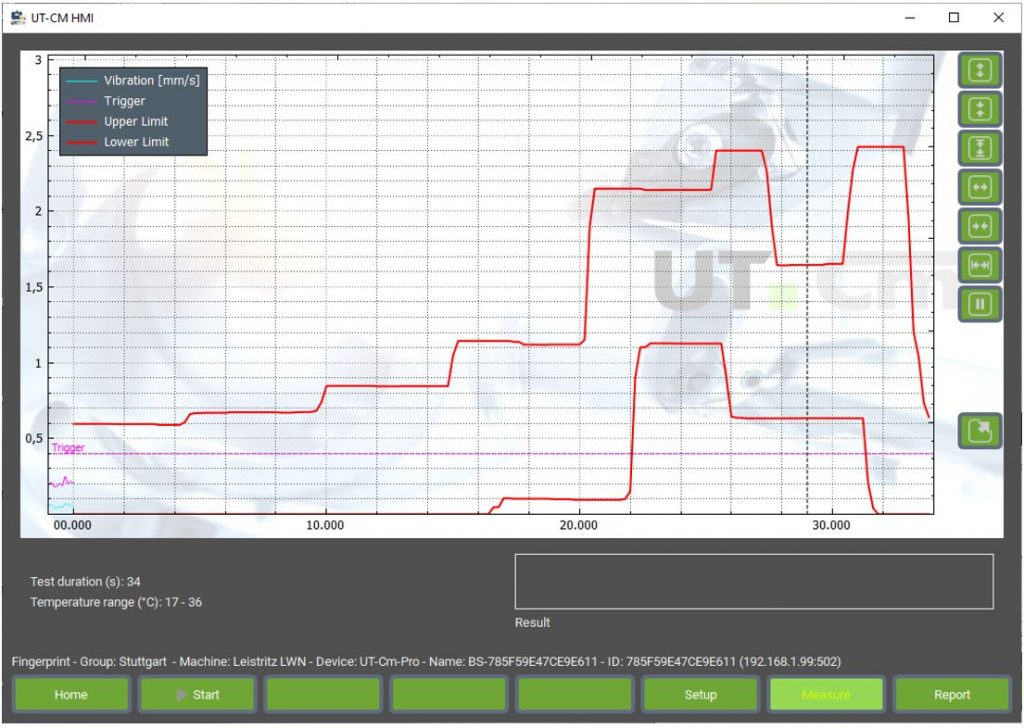

Fingerprint (ECG)

The fingerprint (ECG) is a special function for state and process monitoring. An initial fingerprint containing the data over a defined cycle is recorded and compared with the new record for a later, new capture. This allows conclusions to be drawn about the condition of the system as well as the process itself.

-

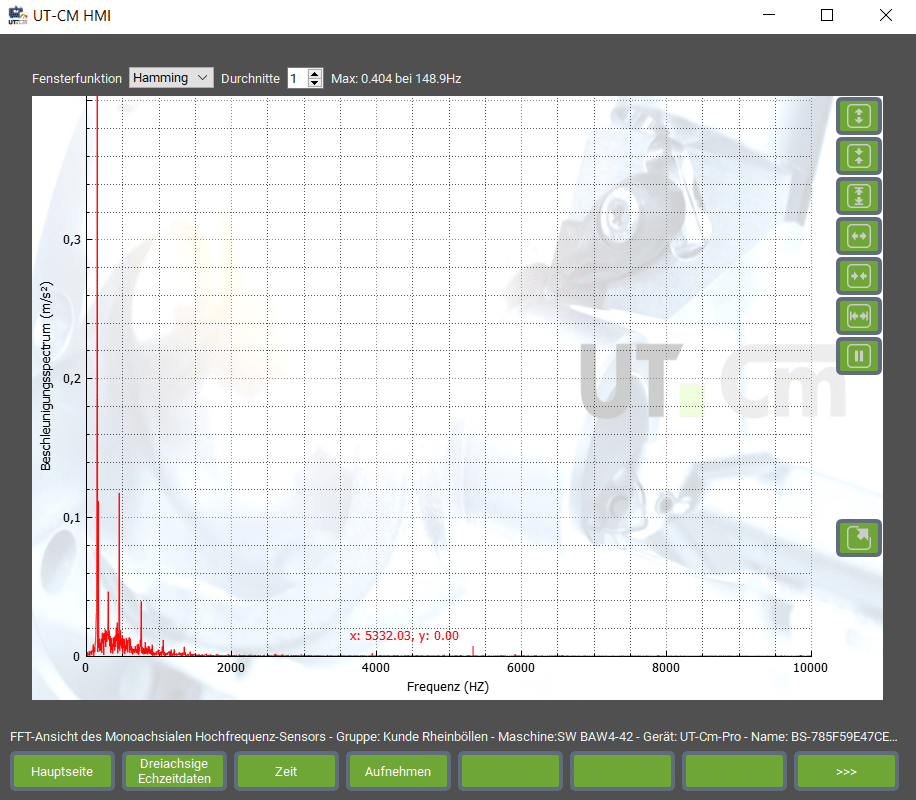

Fourier-Transformation (FFT)

The fast Fourier transformation (English almost Fourier transform, therefore usually abbreviated FFT) is an algorithm for the efficient calculation of the discrete Fourier transformation (DFT). With it, a time-discrete signal can be broken down into its frequency components and thus analyzed.