Your Technology Partner

Added value coupled with efficient use and maximum productivity

-

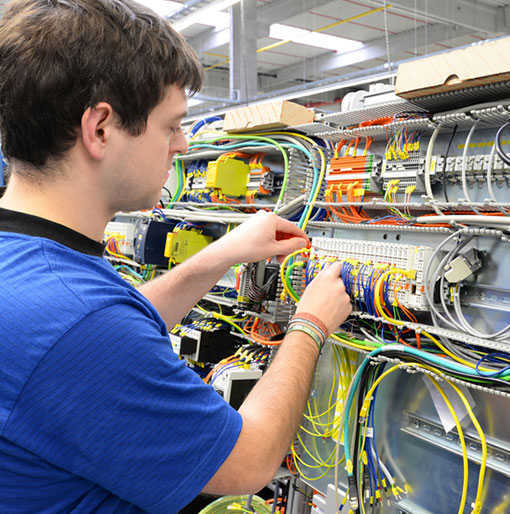

Experts‘ Know-how Creating Optimization Potentials and Synergies

With increasing competition, continually growing cost pressure as well as invariably changing quality requirements, including appropriate verifi cations, companies are forced to analyze and optimize their processes. UTTec GmbH & Co. KG, with decades of experience in machining processes working with the automobile industry, suppliers and aerospace industry, machine construction and mechanical engineering, medical technology as well as in areas of contract manufacturing and tools and mold-and-die production, is the technology partner that with a team of experienced technologists analyzes production and machining processes and offers solutions for their optimization.

If you aim for a higher process capability

as well as a quantifiable productivity, you should work your way up the levels. It’s not always about the how-fast, the how-far or the how-many; it’s more about consistency in production!

In-Process Controlling

This deals with process induced sources of deviation – tool-wear and temperature fluctuations – and gives you via process monitoring intelligent feedback during the machining

Process setup

deals with predictable causes of deviation, such as the position of components, the size of tools and offsets of the machine tools. These sources could otherwise cause deviations on the first workpiece

Process parameters

To achieve a predictable level of production, the sources of deviations have to be traced, and their causes need to be isolated and taken care of one by one. When the basic causes of deviations are directly eliminated, the controlling over process results becomes easier.

-

News

UNITECH Hausmesse 05. – 06. Juni 2024 in Chemnitz (Germany)

UNITECH-Maschinen GmbH invites all interested parties to visit our traditional in-house exhibition. This year you

WSF + SIXT-WZM + SMEC OPEN HOUSE 06. – 08. Juni 2024 in Bissingen an der Teck (Germany)

The companies WSF and SIXT-WZM + SMEC invite all interested parties to visit our in-house

LIMAS in-house exhibition in PD Neer Netherlands – 29-30.05.2024

Our partner LIMAS is organising an in-house exhibition with new technologies. The suppliers from the

CCMT Shanghai 2024

We invite you to the CCMT in Shanghai from 08.04 to 12.04.2024 at stand B409