A system for data analysis

-

The most effective way to analyze data!

-

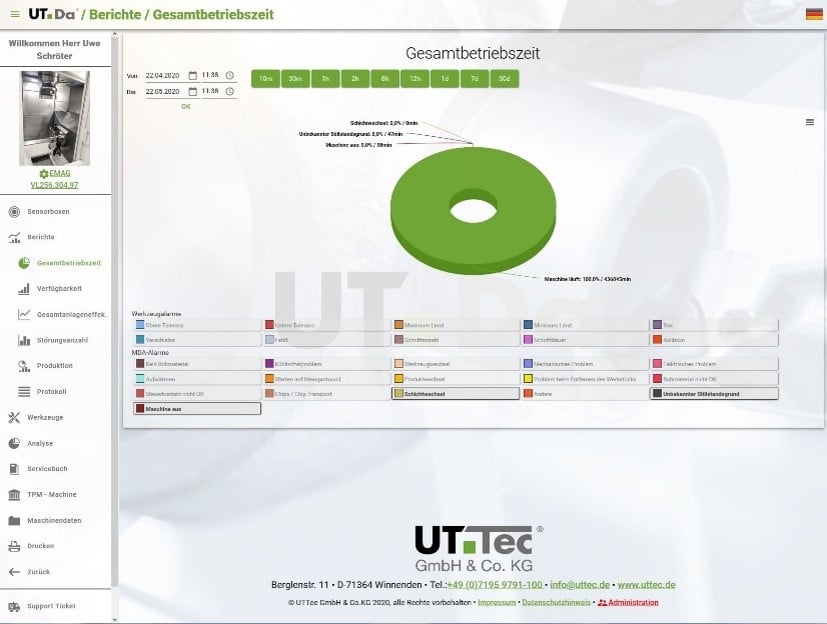

UT-Da® Data analysis via Web-Software

With UT-Da, up to 14 fault reasons can be defined within the MDE.

machine running times, downtimes and non-productive times in detail.

downtimes are recorded in detail. This enables the UT-Da® system to export a detailed PDF protocol.

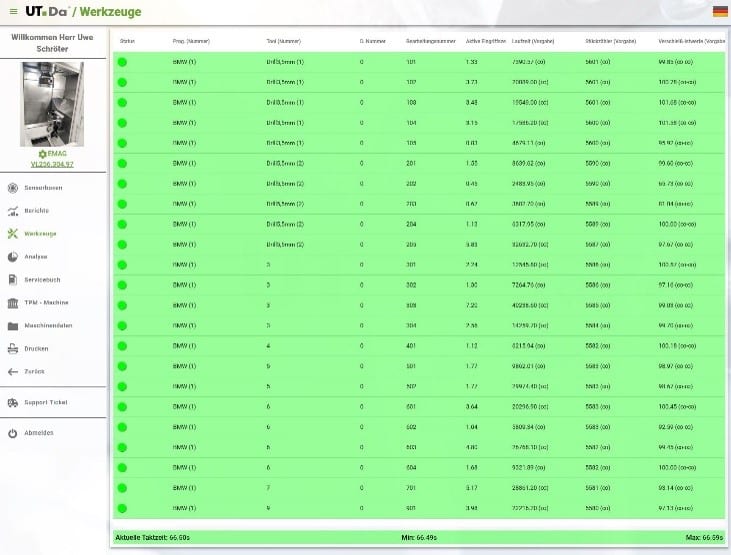

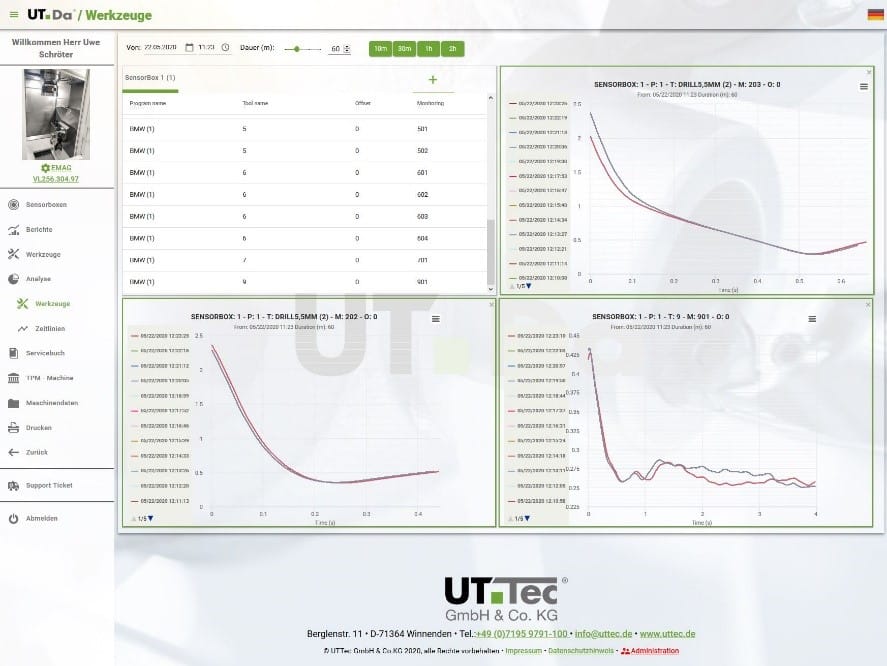

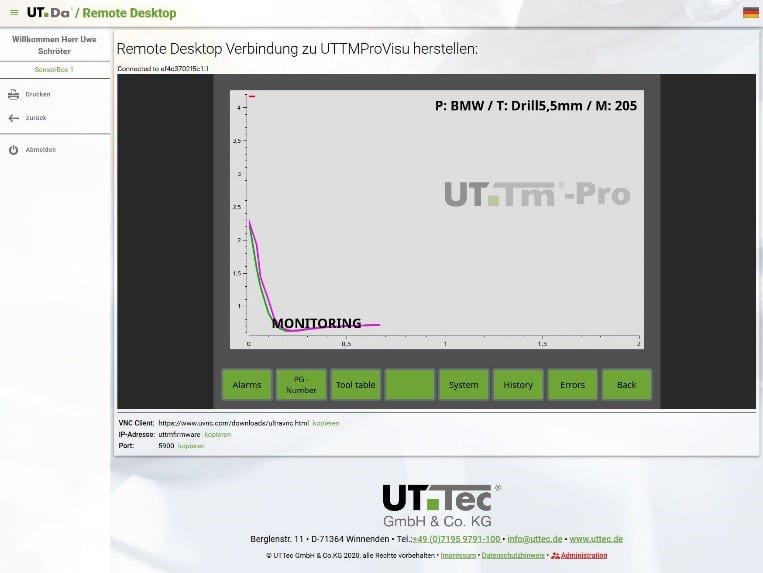

This data analysis also makes all data stored in the tool monitoring system transparent. This means that the wear, the tool data plus the production quantity can be called up on the basis of the data from the tool monitoring. All information from the UT-Tm® system becomes visible via defined times. As a result, cutting parameters can also be changed to generate more stable cycle times.

-

UT-Da® Long-term tool wear

Visualisation of tool wear

During milling, drilling and other machining operations with defined cutting edges, wear occurs that can have a negative effect on the quality of the workpiece (dimensional accuracy, surface quality …). There are typical signs for each type of wear. Thus, a trend detection is possible through different force absorptions.

However, these typical signs can also lead to hairline and comb cracks. In addition, expansions and shrinkages in the material often occur due to temperature fluctuations.

In the event of a plate breakout, the system intervenes immediately to prevent larger forces that could lead to destruction of the tool holder, the machine or the workpiece.

All in all, economic efficiency can be increased through precisely definable tool life

-

UT-Da® Production

- Analyses in production and materials management show the current status, possible performance and cost reduction potentials.

- Planning of production times and production output.

- Determining the cause of these additional costs

- Target-performance analyses to identify unexpected cost increases at an early stage

- Machine comparison in production

-

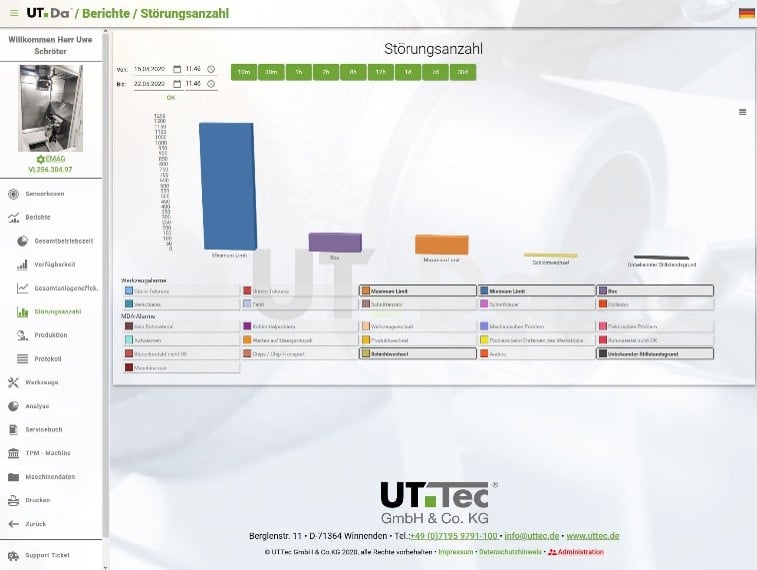

UT-Da® Number of faults

- Reporting of the number of malfunctions from the reasons for malfunction

- Message from tools

- Reporting of standstill

-

UT-Da® Analysis of tools and pre-maintenance

- The tool Analysis supports you in checking and assessing your own use of resources. It also offers ideas and concrete starting points to reduce material and energy used.

- Predictive maintenance, collaborative communication, safety awareness and enterprise integration are redefined through personalisable notices and alerts in real time. This can reduce or even prevent unnecessary maintenance in factories or plants.

-

UT-Da® Site Administration

- Location management: Manage multiple businesses with one access

- One access, manage multiple companies - simple and fast!

- Statistics: Check total production broken down by locations.

- The organisational structure is oriented to the locations and production / processes

-

UTDa ® - Mobile analysis

- The visualisation is WEB-based and can therefore be displayed on Safari, Firefox, Chrome and Microsoft Edge Chromium.

- Export of process data (I4.0) - The DT-Da® process monitoring system makes it possible to view process data such as alarms, MDE messages and cycle times on mobile devices.

- Operation and analysis of the process monitoring in the network.

- Remote access to the UTTec systems

-

UTDa ® - Industry 4.0

- The interface is adapted for mobile devices.

- UT-Da® uses an SQL database internally in which all the data required for the display is stored; data in the SQL database can be freely read by customers.

- A cross-location administration is available in the system available.

- Total Productive Maintenance (TPM) with timer for chucks, turrets, etc.