UT-Cm®-Basic Version

This system is not only used to detect collisions but also helps to detect them and prevent major damage

A collision monitoring system

-

The most effective way to monitor machines!

- Collision alarm less in 2ms.

- Temperature alarm

- Sensor with M12x1and 42mm long

- Overloading alarm

- Events data logging

-

UT-Cm®-Basic Version – Overview of all functions

UTTec UT-Cm®-Basic for Machine Tools is a system for the monitoring and control of machine tools, which the following purposes:

- Collision alarm less in 2ms.

- Sensor with M12x1and 42mm long

- Overloading alarm

- Temperature alarm

- Programmable limits

- Events data logging

- Real-time data for process-monitoring

- HMI (Windows XP, Win7, WIN10 , LINUX)

- UT - Cm® - Network – Software

- Continuous monitoring (5 days battery)

-

Always connected

The always-connected interface and multi-platform software allow to have the full control anywhere, obtaining the maximum results from your machine.

-

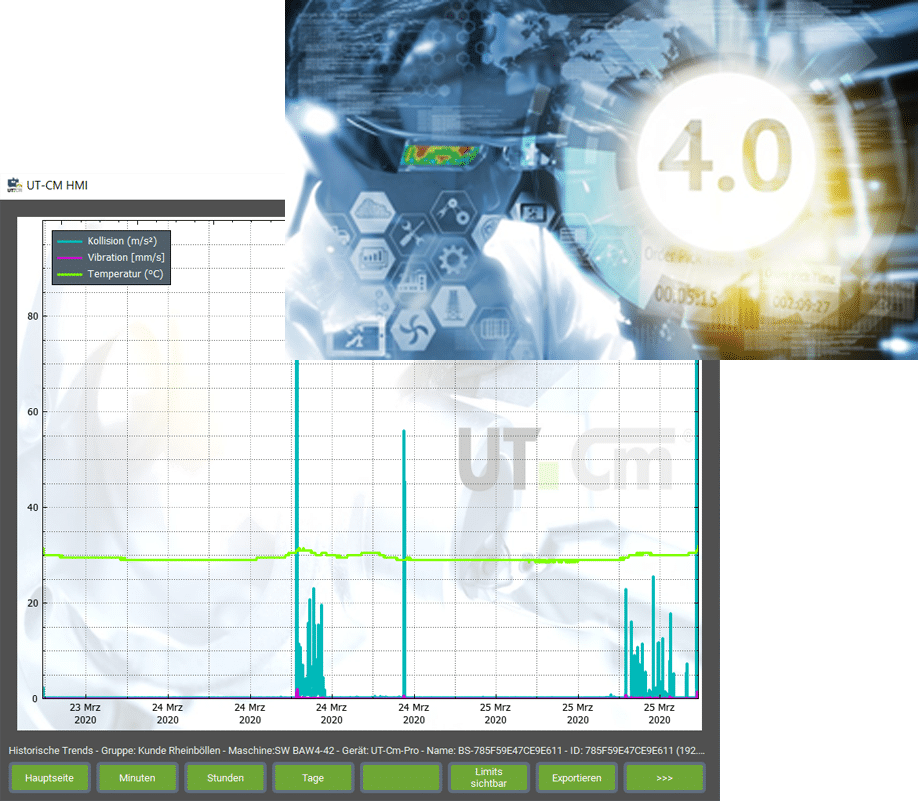

Dashboard

HMI UT-Cm® was developed to guarantee simplicity and intuitiveness in order to make you understand all the useful information at a glance. The system allows the interaction with more sensors to facilitate the complete monitoring of your machines.

The system enables interaction with several sensors as a complete monitoring of your machines facilitate.

-

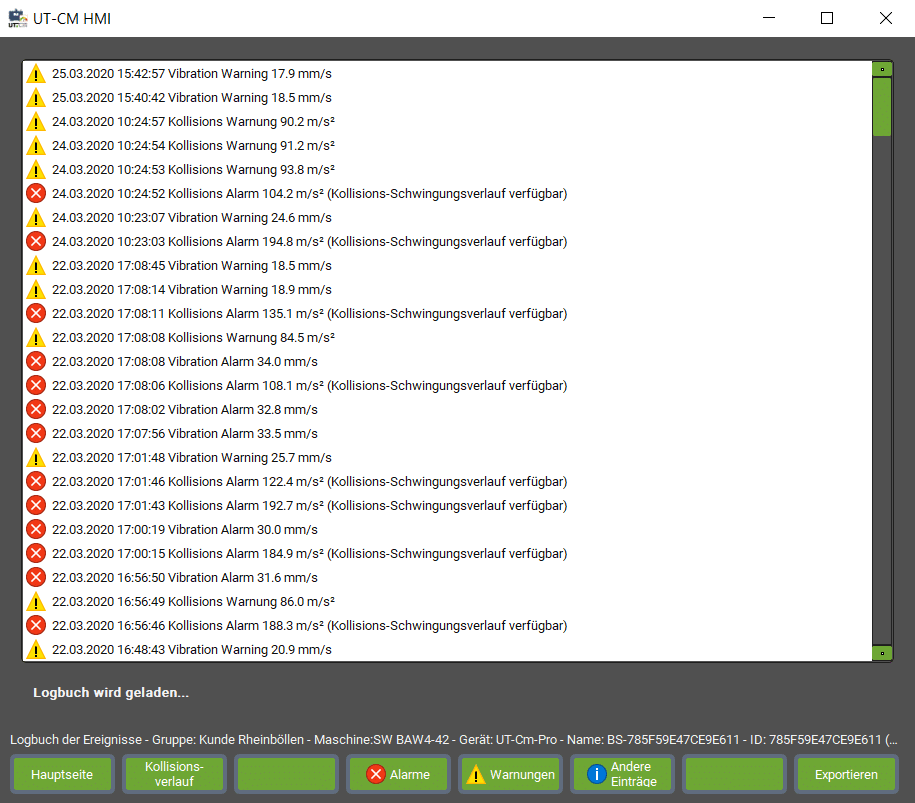

Events – Logbuch details

The advantage of the events session is to look at your machine history, recording all activities with an intuitive infographic that includes the following functions:

Alarms, Warnings, Check-Up and Downtimes.

-

Real Time Data – Status RMS AXIS

Through the 3 factors visualization you can monitor in a single moment the productive process.

The HMI UT-Cm® allows to export the evident information in every moment in real or non-real time, to manage data in complete autonomy

-

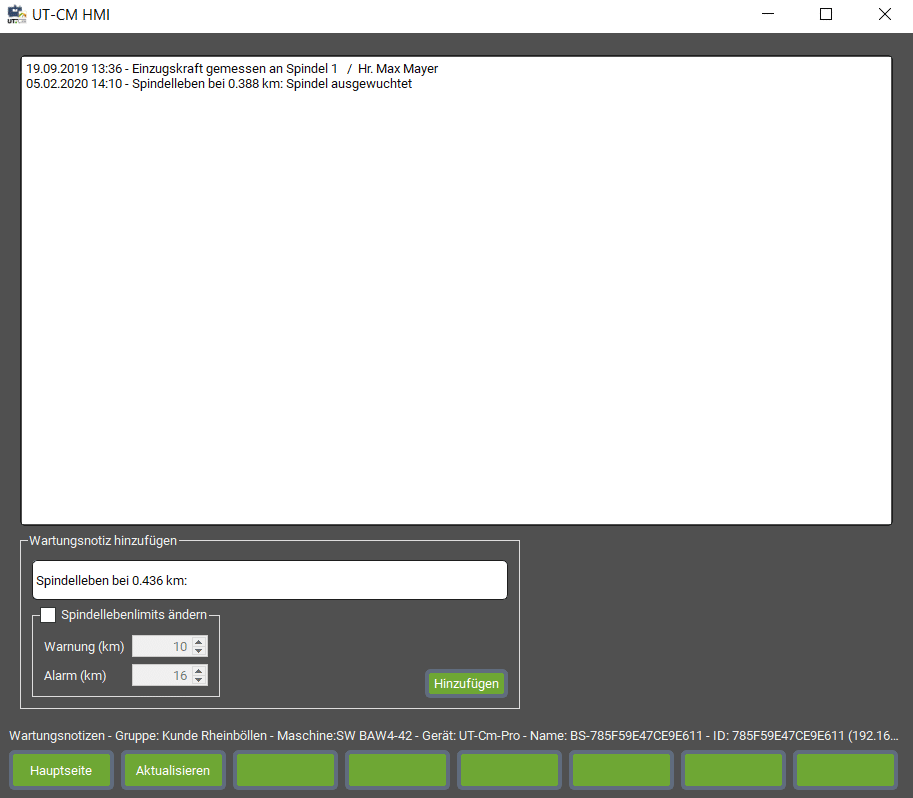

Maintenance Notes

Maintenance notes are understood to create exactly a service report of what everyone has performed on the spindle in maintenance or service. This information is the basis of the preventive maintenance history.

-

FACTORY CONTROL (Optional)

Mit UT-Cm® Sensor können Sie einfach eine Produktionslinie oder entfernte Anlagen anschauen damit die Innovative Überwachung durch die Integration unserer SAM-Software (Smart Asset Monitoring). Integration bei der Instandhaltung / Service erlaubt es Ihnen, in einem einzigen Dashboard alle angeschlossenen Systeme und Maschinenzustände zu sehen, um einige KPI durchzuführen, Registrierung von Alarmereignissen und Echtzeitkollision, Vibrationen, Profile und Maschinen zu warten